Advantages of Edge Clad

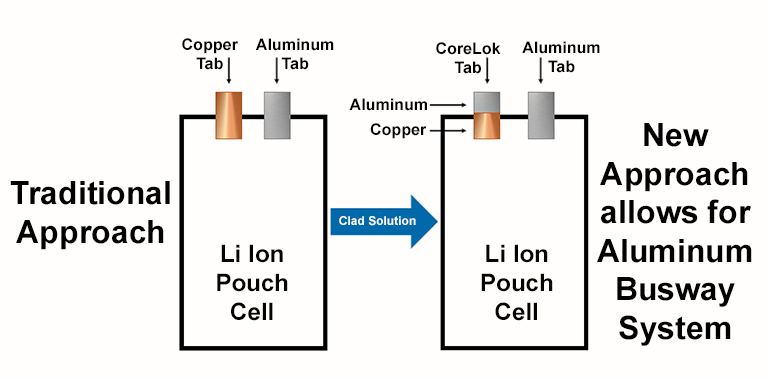

CoreLok® edge clad copper to aluminum provides superior electrical conductivity, mechanical strength and thermal performance. The strength of the CoreLok® joint exceeds that of the aluminum alloy. This material can be used to join copper and aluminum battery tabs in a busway system or to replace copper tabs with copper/aluminum tabs allowing for an all aluminum busway design.

Copper Aluminum Corelok® provides a low cost high performance solution for li-ion battery tab joining. The leads or tabs from Li-ion pouch and prismatic cells are often configured with one lead of copper and the other lead of aluminum. This creates a challenge for joining copper to aluminum with the busbar. By replacing one of the leads with a Corelok® lead, the busbar joining can be applied to all aluminum to aluminum connections. This greatly simplifies the welding process.